DOUBLE ECCENTRIC VALVES

DOUBLE ECCENTRIC VALVES

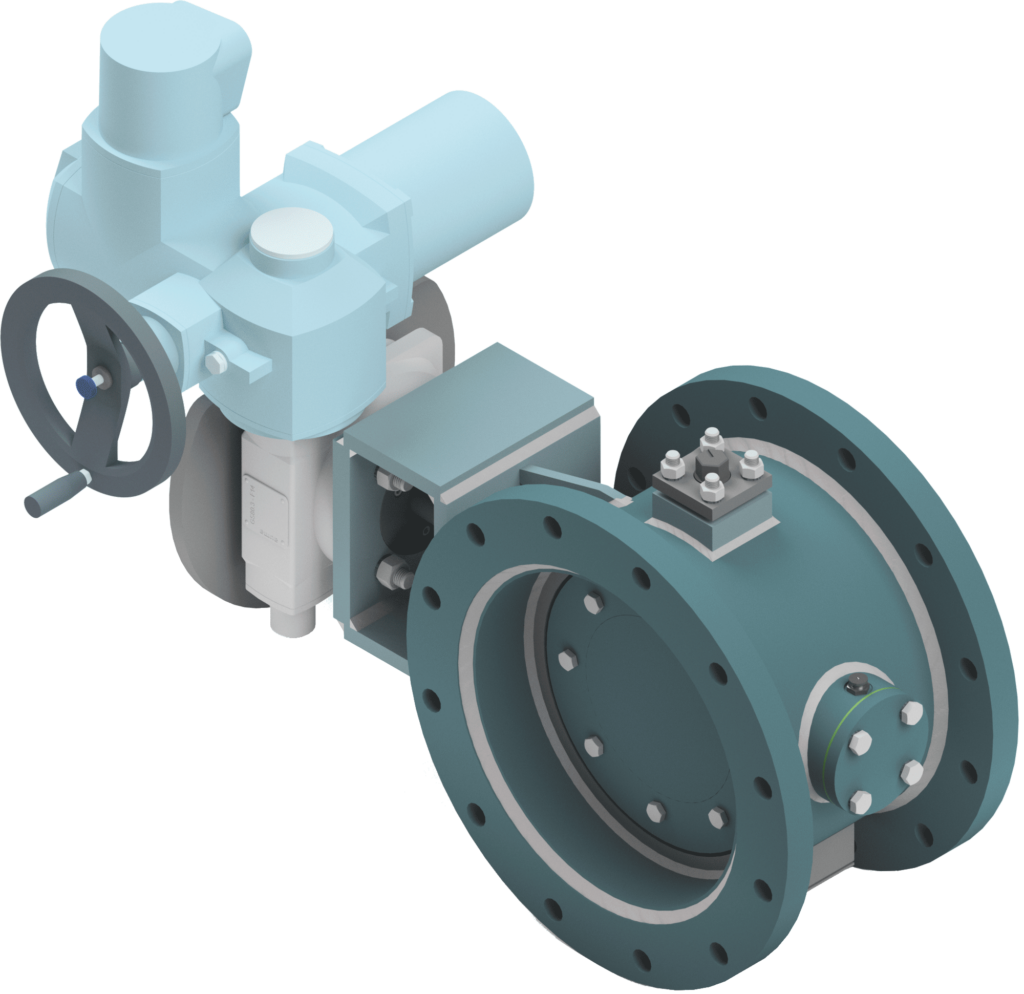

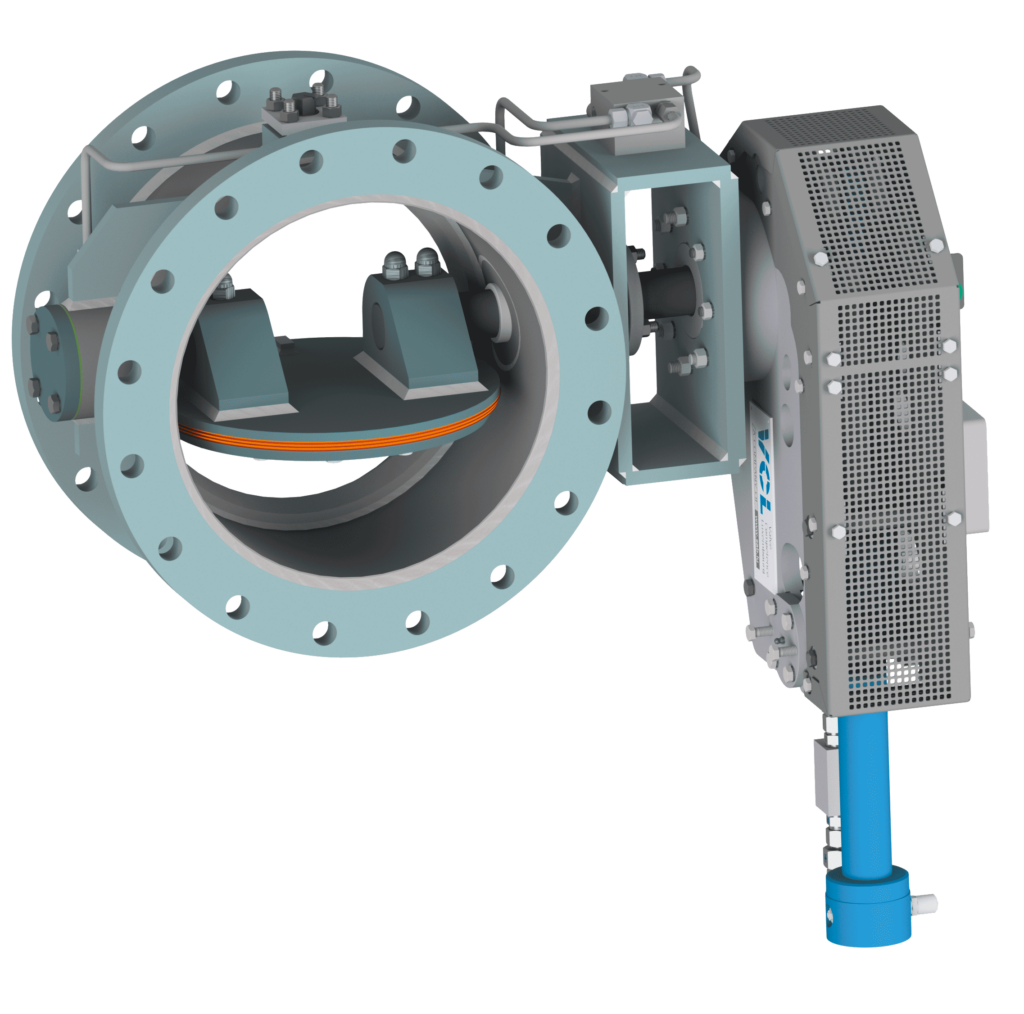

The VCL Double Eccentric Valve is a shut-off and control device designed for gaseous media in different industries, e.g. Iron & Steel, Non-Ferrous, Glass or Petrochemical. Due to a self-tightening effect, the Double Eccentric Valve ensures a perfect tightness in the preferred pressure direction. Related to a standard shut-off valve, the friction in the seat area is significantly reduced which leads to a long lifetime and low actuation torques. The rotation-symmetric sealing system allows an economic manufacturing and a simple installation of spare sealings in all suitable materials, reaching from different types of elastomers up to metallic compound sealings for high temperatures up to 600 °C. This valve can be installed in any position and fitted with different mechanisms (pneumatic, manual, electric or hydraulic).

DESIGN FEATURES OF

DOUBLE ECCENTRIC VALVES

- Fabricated construction

- Valve actuation in accordance with customer‘s

requirements (man. / electr. / hydr. / pneum.) - Internal and external (high temperature) shaft bearings

- Pressure rating up to 6.0 bar

- Service temperatures up to 600 °C

- Nominal sizes up to DN 3000

- Other sizes or operating conditions on request

DESIGN

ADVANTAGES

- Almost no wear at the seats due to parallel and friction free opening and closing at the valve disc

- Valves can be used in gas- and steam (vapours) loaded atmopshere (incl. vacuum applications)

- Opening against full differential pressure

- Minimal friction and wear due to double eccentric geometry

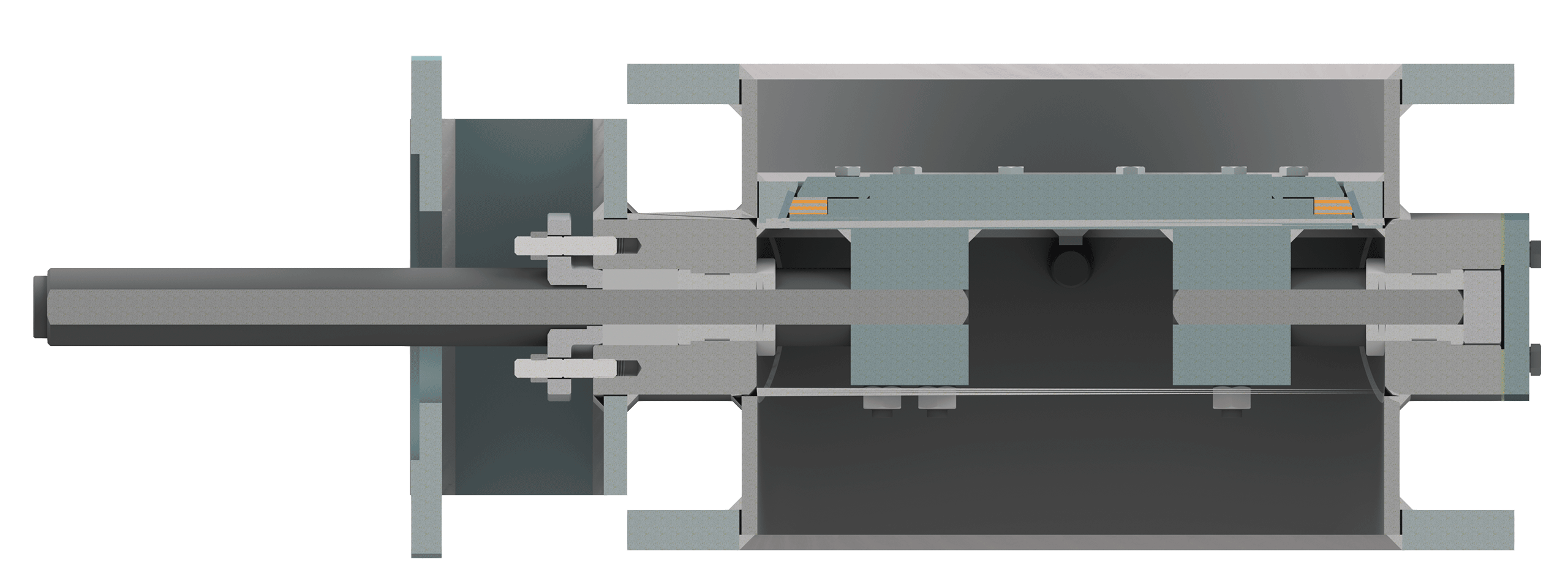

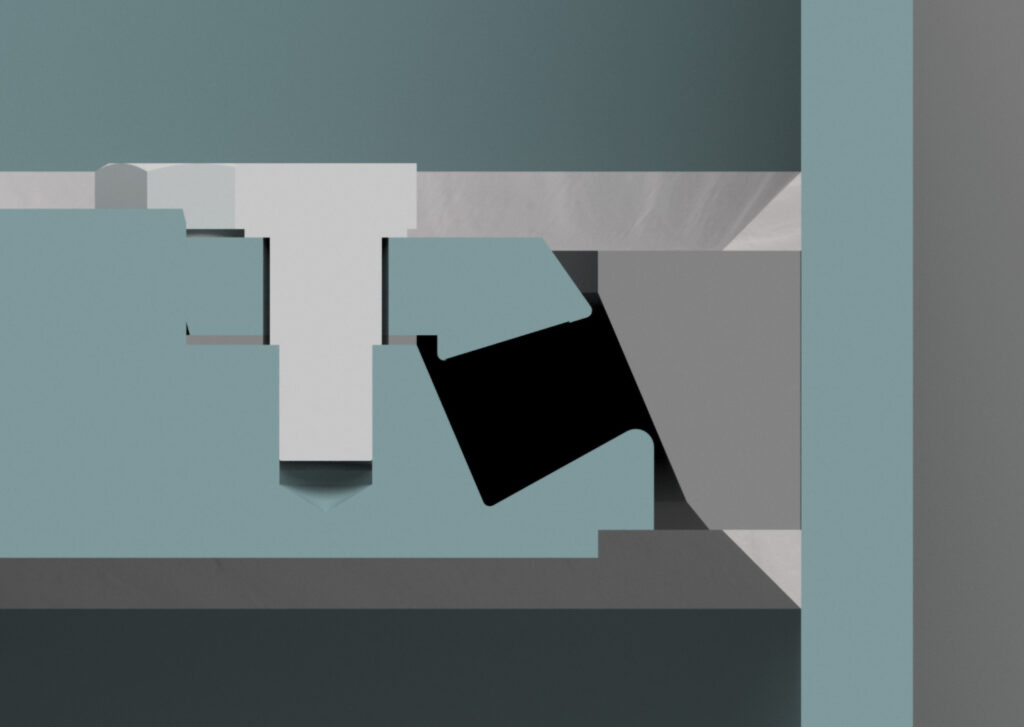

Closed double eccentric valve with actuator

Open double eccentric valve with hydraulic actuator

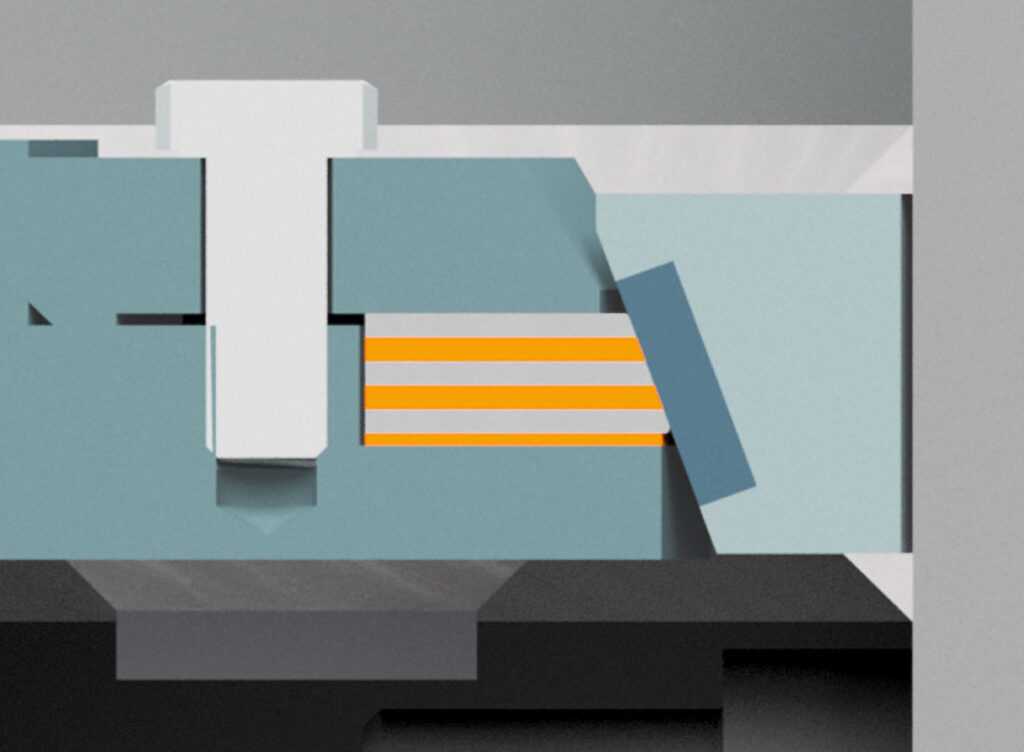

METAL-TO-METAL

up to 600 °C

RESILIENT SEALING

(silicone, viton, graphite etc.)

up to 300 °C*

* depending on sealing material